The right choice isn’t about OEM vs. Aftermarket, but about selecting parts engineered to survive the unique demands of Canadian driving.

- Generic parts often lack the material resilience for extreme cold and road salt, leading to premature failure and higher long-term costs.

- Your warranty is protected by Canadian law, but you must keep meticulous records to defend it.

Recommendation: Prioritize parts with proven performance in Canadian conditions—whether OEM, certified aftermarket, or even high-quality used original parts—over the cheapest available option.

For any Canadian car owner, the moment a repair bill lands is a familiar crossroad. On one side, the dealership offers Original Equipment Manufacturer (OEM) parts, promising perfect fit and quality at a premium price. On the other, the aftermarket presents a vast, often confusing, landscape of alternatives that are significantly cheaper. The conventional wisdom frames this as a simple trade-off between cost and quality. You can save money now but might be taking a risk, or you can pay more for peace of mind.

This binary choice, however, misses the most critical factor for Canadian drivers: our environment. The real battle isn’t just between an OEM box and a generic one; it’s between a component’s material science and a relentless barrage of road salt, thermal shock from -30°C to +30°C, and freeze-thaw cycles that attack metal, rubber, and electronics. The generic advice to « shop around » or « check your warranty » is insufficient when a failed sensor can compromise your vehicle’s stability control on an icy highway.

But what if the key wasn’t simply choosing the manufacturer’s brand, but choosing parts specifically proven to withstand these uniquely Canadian challenges? This guide moves beyond the simplistic cost-versus-quality debate. We will dissect the problem from a supply chain and engineering perspective, focusing on the concept of ‘Engineered-for-Canada’ resilience. It’s about understanding not just the part, but its long-term impact on your vehicle’s system integrity and your total cost of ownership in a high-wear environment.

This article will provide a clear framework for making these critical decisions. By examining certification, warranty rights, material science, and strategic parts selection, you’ll learn how to navigate the complex world of auto parts with the confidence of an expert.

Summary: OEM vs Aftermarket Parts: Which Should You Choose for Repairs?

- Why CAPA certification matters for aftermarket bumpers and hoods?

- Can a dealer legally void your warranty for using an aftermarket oil filter?

- Why cheap aftermarket sensors often fail within 6 months?

- The 3 engine components you should never replace with generic parts

- When is a used original part better than a new aftermarket one?

- Why can’t your local neighborhood mechanic fix an aluminum hood?

- The $2,500 shock absorber: Preparing for the maintenance bill

- The « Million Kilometer » Mindset: Fighting Salt and Thermal Shock

Why CAPA certification matters for aftermarket bumpers and hoods?

When it comes to cosmetic and collision parts like bumpers and hoods, the aftermarket can offer significant savings. However, quality and safety are paramount. This is where the Certified Automotive Parts Association (CAPA) provides a crucial layer of trust. CAPA is an independent, non-profit standards organization that tests and certifies aftermarket parts to ensure they are functionally equivalent to their OEM counterparts. With over 174 million replacement parts having earned CAPA Certification, it stands as a significant benchmark for quality in the industry.

The CAPA 501 standard for bumpers, for example, involves dynamic crash tests at extreme temperatures, simulating real-world impacts to verify performance. This is not just a visual inspection; it’s a rigorous engineering validation process. For a Canadian consumer, a CAPA sticker means the part has been proven to fit, perform, and last like the original.

However, certification alone doesn’t solve every problem. The Canadian insurance and repair industry faces a specific challenge: availability. In a case study on parts handling, Canadian insurance companies identified CAPA as the « only technically traceable standard » they trust for claims. Yet, these same companies report ongoing frustration with the lack of CAPA-certified parts for popular Canadian models like the Ford Focus. This creates a supply chain friction where the desire for a quality-assured part clashes with the practical need to complete a repair in a timely manner, forcing shops and consumers into difficult decisions.

Can a dealer legally void your warranty for using an aftermarket oil filter?

This is one of the most significant fears for car owners: that saving a few dollars on an aftermarket part will result in the voiding of a multi-thousand-dollar manufacturer’s warranty. In Canada, the answer is not a simple yes or no. A dealership cannot legally void your entire vehicle warranty simply because you used an aftermarket part. The burden of proof lies squarely on them. They must formally prove, often through an engineering report, that the specific aftermarket part you installed was the direct cause of a failure for which you are seeking warranty coverage.

According to the experts at NerdWallet, « if the part causes an issue that then needs to be repaired, and a dealership can prove that the aftermarket part caused the problem, it could deny warranty coverage for that specific repair. » Notice the specificity: coverage is denied for that single repair, not the entire vehicle warranty. To protect yourself, meticulous documentation is your best defense. Using reputable aftermarket brands with a strong Canadian presence, such as NAPA or MotoMaster, can also add a layer of credibility to your maintenance choices.

If a dispute arises, you are not without recourse. Your rights are protected under provincial consumer protection acts, and organizations like the Canadian Motor Vehicle Arbitration Plan (CAMVAP) exist to mediate such conflicts. Being prepared with comprehensive records is the key to leveraging these rights effectively.

Your Action Plan: Protecting Your Warranty in Canada

- Keep detailed maintenance records with dates, mileage, and receipts for all aftermarket parts installed.

- Use reputable aftermarket brands with a strong Canadian presence.

- Request written documentation from the dealer if they claim an aftermarket part caused the damage.

- Understand that dealers must provide formal engineering reports linking the specific part to any failure.

- Know your rights under provincial consumer protection acts, which place the burden of proof on the dealer.

Why cheap aftermarket sensors often fail within 6 months?

A modern vehicle relies on a complex network of sensors—for wheel speed, oxygen levels, camshaft position, and more. While a cheap aftermarket sensor might look identical to its OEM counterpart, its premature failure is often a question of material science and testing standards. Canadian winters are a brutal proving ground, and many generic sensors are simply not engineered to survive the extreme conditions, particularly the one-two punch of thermal shock and salt ingress.

The difference lies in the hidden specifications. OEM sensors are validated for extreme temperature ranges (e.g., -40°C to +85°C), use automotive-grade solder designed for thermal cycling, and are sealed with high-quality gaskets or potting compounds to achieve IP67/68 ratings against moisture and dust. They undergo hundreds of hours of salt spray testing. Cheap aftermarket versions often cut corners in these invisible but critical areas.

The table below highlights the stark differences in material and testing standards that directly impact longevity in a harsh climate like Canada’s.

| Factor | OEM Sensors | Cheap Aftermarket |

|---|---|---|

| Temperature Range | -40°C to +85°C validated | Often -20°C to +70°C |

| Seal Quality | IP67/68 rated seals | Basic rubber gaskets |

| Solder Quality | Automotive-grade, thermal cycling tested | Standard consumer electronics grade |

| Potting Compound | Silicone-based, flexible at extreme temps | Epoxy-based, becomes brittle in cold |

| Salt Spray Testing | 500+ hours standard | Often untested or <100 hours |

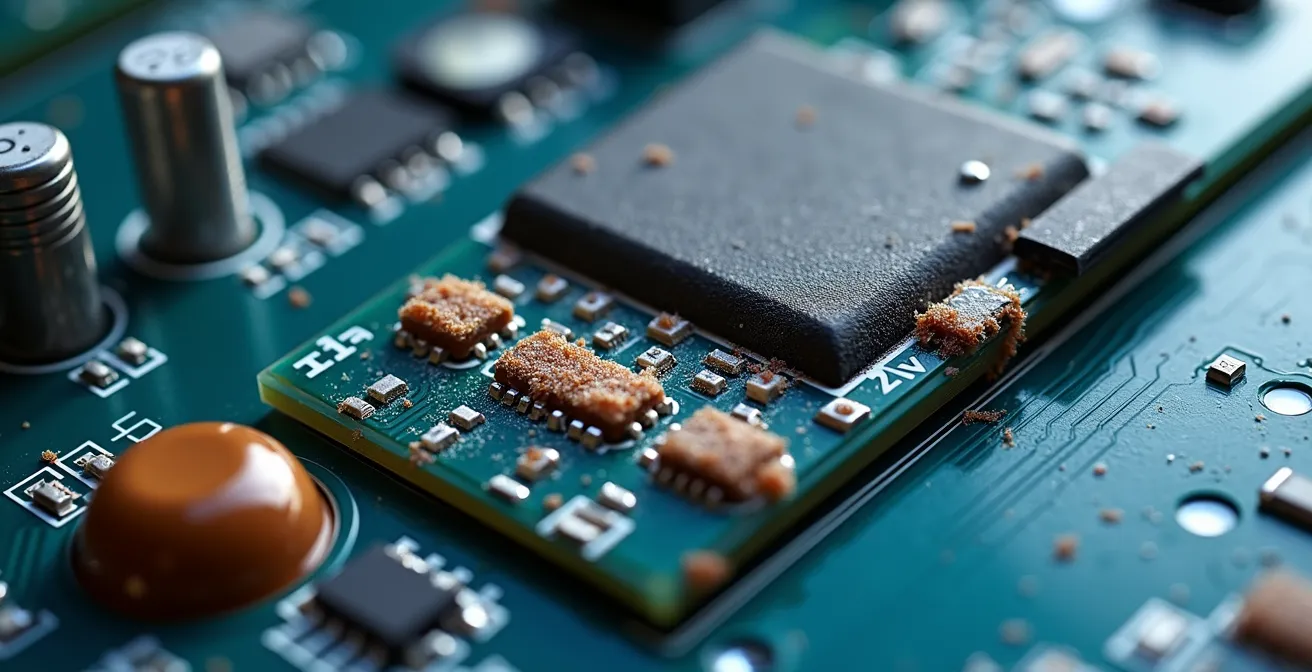

The result of these inferior materials is predictable. A brittle epoxy potting compound cracks in the cold, allowing moisture from road spray to penetrate the housing. The compromised seals let in salt, which quickly corrodes the consumer-grade solder on the circuit board. What started as a $50 saving on a sensor can lead to a flashing check engine light, compromised safety systems, and another repair bill just a few months later.

As this image reveals, the internal damage caused by moisture and salt is catastrophic at a micro level. This is the tangible result of a part not being engineered for the realities of Canadian roads.

The 3 engine components you should never replace with generic parts

While some aftermarket parts offer a reasonable balance of cost and quality, there are certain engine components where the risk of failure is too high, especially given Canada’s extreme cold-start conditions. For these critical parts, the engineering tolerances and material specifications of the OEM are non-negotiable for ensuring vehicle reliability and longevity. The rising cost of repairs, which as Statistics Canada data reveals saw a 22.3% increase from 2019 to 2024, makes avoiding a catastrophic engine failure even more critical.

When the integrity of your engine is at stake, opting for OEM is not a luxury; it’s a strategic investment in reliability. Experts in Canadian automotive maintenance consistently identify three components where you should never compromise:

- Timing Belt/Chain & Tensioner: This system is the heart of your engine’s synchronization. During a -30°C cold start, engine oil viscosity is extremely high, placing immense stress on the tensioner and belt/chain. OEM components are specifically designed and tested for this cold-start reliability, a scenario many generic parts are never validated for. Failure here is catastrophic and will destroy the engine.

- Fuel Pump: An OEM fuel pump is engineered for consistent pressure delivery across a wide temperature range and is built to be compatible with the specific ethanol blends found in Canadian gasoline. Aftermarket pumps can struggle in frigid temperatures, leading to hard starts, stalling, and lean running conditions that can damage the engine over time.

- Ignition Coils: OEM ignition coils feature superior housing materials and sealing to prevent moisture intrusion. In Canada’s constant freeze-thaw cycles, micro-cracks can form in the plastic housings of cheaper aftermarket coils, allowing moisture to seep in and cause misfires or complete failure, leaving you stranded.

For these parts, the OEM’s system-wide testing and validation for extreme temperatures provide a margin of safety that a reverse-engineered aftermarket part simply cannot guarantee. The potential cost of failure far outweighs any upfront savings.

When is a used original part better than a new aftermarket one?

The debate isn’t always between a new OEM part and a new aftermarket part. A third, often overlooked, option provides an excellent balance of quality and cost: a used OEM part from a reputable salvage yard. This is particularly true for complex electronic modules and major structural components, where the original manufacturer’s engineering offers a distinct advantage over a generic new part.

Consider the Body Control Module (BCM) or Engine Control Unit (ECU). These are the electronic brains of your vehicle. Aftermarket companies often struggle to perfectly replicate the software, especially for Canadian-specific features like mandatory daytime running lights, metric instrument cluster displays, or block heater logic. A used OEM module from a donor vehicle maintains all the correct, region-specific programming. This avoids the compatibility nightmares and costly reprogramming fees that can arise when trying to integrate a « universal » aftermarket module into a system that expects specific Canadian code.

The same logic applies to structural parts in rust-prone regions of Canada. The quality of the steel and the thickness and type of the factory e-coating on an OEM subframe or control arm are typically far superior to that of a cheap aftermarket replacement. A rust-free used OEM part sourced from a dry province (like Alberta or Saskatchewan) will often provide a much longer service life than a brand new, poorly coated aftermarket part that will begin to show surface rust after its first salty winter. In this case, the original material’s resilience is more valuable than the « newness » of the replacement.

Why can’t your local neighborhood mechanic fix an aluminum hood?

The increasing use of aluminum in vehicle bodies, driven by the need for lighter, more fuel-efficient cars (like the popular Ford F-150), has introduced a new layer of complexity to collision repair. This shift goes beyond the part itself and into the realm of the repair environment. Your trusted local mechanic, who has expertly repaired steel panels for decades, likely cannot properly repair an aluminum hood, door, or fender. It’s not a matter of skill, but of specialized equipment and process.

Aluminum repair requires a completely isolated environment. Steel and aluminum are subject to galvanic corrosion when they come into contact. Even tiny steel particles from a grinder or a wire brush left on an aluminum panel can create a corrosion cell that will bubble the paint from underneath months later. For this reason, certified aluminum repair facilities use a dedicated, quarantined repair bay with a separate set of tools—grinders, sanders, dollies, and hammers—that never touch steel. The air filtration systems are also more robust to prevent cross-contamination.

This necessity for a ‘clean room’ environment explains why aluminum repair is a specialized, and more expensive, service often found only at larger collision centres or dealerships. While many shops are increasing their use of aftermarket parts for standard repairs, as noted in one survey where they cite « lower prices, more immediate availability, and quality that’s equal to or better than the OEM part, » this logic does not apply when specialized labour and environments are non-negotiable.

The $2,500 shock absorber: Preparing for the maintenance bill

The sticker shock for modern replacement parts often comes from complex, electronically-controlled systems. A shock absorber is no longer just a simple hydraulic damper; on many modern SUVs and luxury vehicles, it’s a sophisticated « strut » integrated with sensors, solenoids, and a central control unit. Systems like GM’s MagneRide, Audi’s Adaptive Air Suspension, or Mercedes’ AIRMATIC can dramatically improve ride quality and safety, but they come with a maintenance bill to match. Replacing a single electronic strut can cost upwards of $1,500-$2,500 in Canada.

This is where the aftermarket offers a tempting alternative, not just in cheaper parts but in « delete kits » that replace the electronic system with conventional passive shocks for a fraction of the price. While this saves a significant amount of money upfront, it comes with a serious, often undisclosed, trade-off in safety. These systems are deeply integrated with the vehicle’s stability and traction control systems. Disabling the adaptive suspension by using a delete kit can cause the vehicle’s safety software to malfunction, as it no longer receives the expected data from the suspension. This can lead to unpredictable handling in emergency maneuvers—a risk that is magnified on icy Canadian roads.

The cost comparison below, using typical Canadian market pricing, illustrates the financial dilemma and the associated safety implications.

| Vehicle System | OEM Part Cost (CAD) | Aftermarket Options | Safety Implications |

|---|---|---|---|

| GM MagneRide (Single Strut) | $1,500-$2,000 | Delete kits available ($400) | Disables stability control features |

| Audi Adaptive Air Suspension | $2,000-$2,500 | Coilover conversion ($1,200) | Loses load-leveling capability |

| Mercedes AIRMATIC | $1,800-$2,200 | Limited quality alternatives | Affects ride height sensors |

While a study found that 50% of total parts purchases from independent repair shops are aftermarket, this statistic doesn’t capture the critical safety compromises made in cases like electronic suspension. The « cheaper » option may fundamentally alter the vehicle’s designed safety envelope.

Key Takeaways

- The decision is not just OEM vs. Aftermarket, but a calculation of a part’s resilience to Canadian salt and cold.

- Your warranty rights are protected by law in Canada, but robust record-keeping is your best defense.

- For critical engine and safety system components, the engineering and testing of OEM parts provide a non-negotiable margin of safety.

The « Million Kilometer » Mindset: Fighting Salt and Thermal Shock

Choosing the right part for a single repair is a reactive decision. Adopting a « Million Kilometer » mindset, however, is a proactive strategy focused on vehicle preservation and maximizing its lifespan in the face of Canada’s harsh environment. This approach views every component not in isolation, but as part of a system that must be protected against the relentless attack of corrosion and thermal shock. It’s about shifting from minimizing the cost of one repair to minimizing the total cost of ownership over many years.

This mindset directly influences part selection. It means prioritizing OEM for underbody components like brake and fuel lines, where the superior quality of the factory anti-corrosion coatings provides the best long-term defense against road salt. It also means being strategic with the aftermarket, choosing engineered-for-Canada brands like Mevotech TTX or Moog Problem Solver series for chassis parts, which are specifically designed with enhanced durability for our conditions.

A core element of this strategy is preventative maintenance designed to combat environmental wear. This isn’t just about following the manufacturer’s schedule; it’s about adding Canada-specific measures.

- Schedule annual undercoating applications with trusted Canadian brands like Krown or Corrosion Free to create a barrier against salt.

- Treat brake rotors and pads as « sacrificial » components, planning to replace them every few winters to protect the more expensive calipers from seizing due to corrosion.

- Proactively inspect and replace rubber components (bushings, boots, hoses) before they show signs of hardening or cracking, as cold temperatures will accelerate their failure.

- Meticulously document all corrosion prevention measures, which provides a significant advantage when it comes to preserving the vehicle’s resale value.

Ultimately, this approach reframes the OEM vs. aftermarket debate. The best choice is the one that contributes to the long-term structural and mechanical integrity of the vehicle, transforming your car from a depreciating asset into a durable investment.

Protect your investment by applying this « million-kilometer » mindset to every service and repair decision, ensuring your vehicle is equipped to handle everything Canadian roads throw at it.

Frequently Asked Questions on OEM vs. Aftermarket Parts

Are remanufactured OEM parts a good alternative?

Yes, remanufactured OEM parts are original parts that have been repaired and tested to original specifications. They meet the same standards as new parts at a fraction of the price, offering an ideal compromise between cost and quality.

When should I definitely choose used OEM over new aftermarket?

For major structural components like subframes and control arms in rust-prone areas, a rust-free used OEM part from a dry province often outlasts a new aftermarket part with inferior coating. The OEM steel quality and e-coating are typically superior.

How do I verify a used OEM part is genuine?

Look for manufacturer part numbers stamped or molded into the component, check VIN compatibility with the donor vehicle, and purchase from reputable salvage yards that guarantee authenticity.